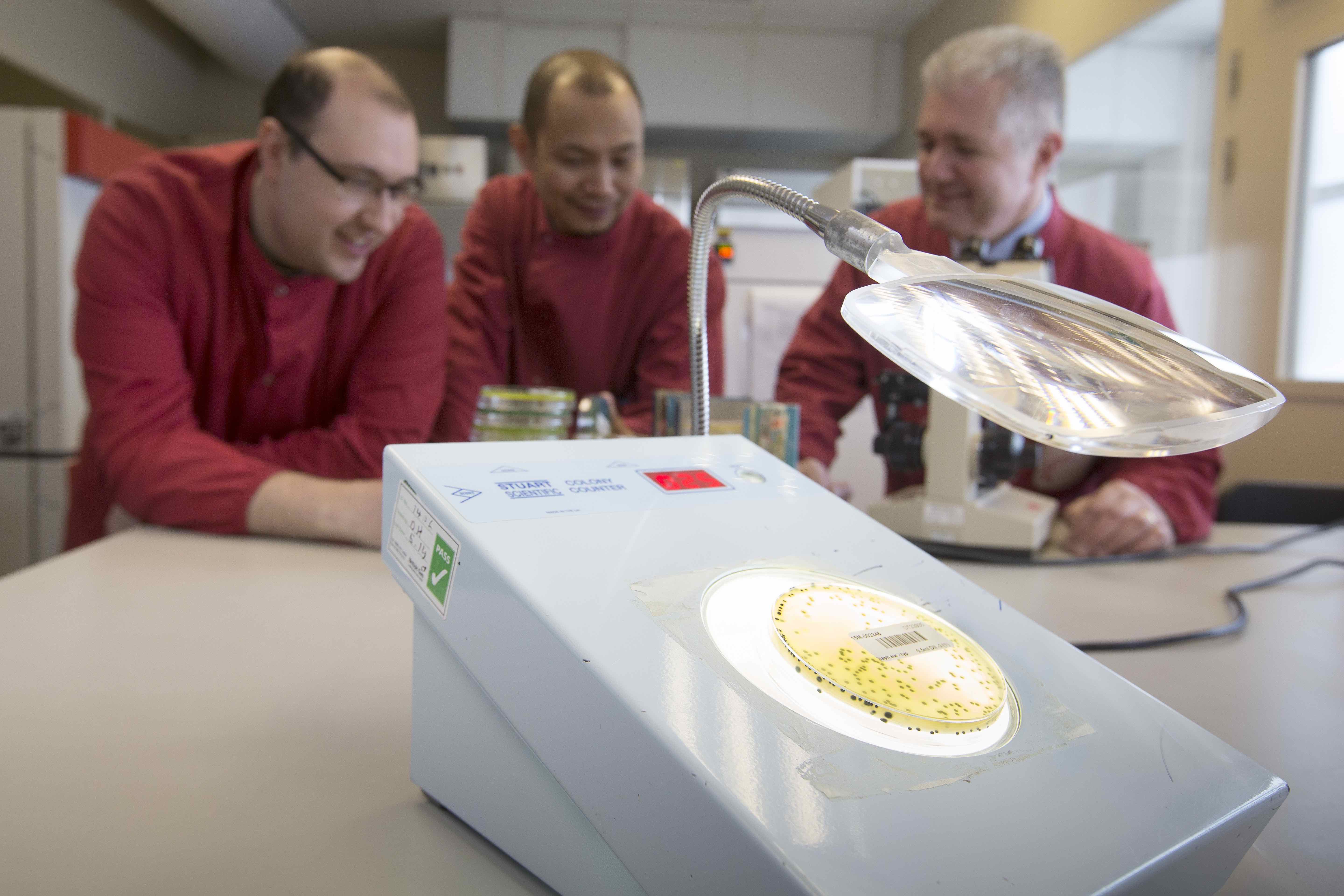

Microbiology

Maintenance of product safety and quality throughout shelf life is the aim of all food producers.

Deterioration due to microbial activity can be a major threat to both the quality and safety of most food products. It is therefore essential that a systematic approach is taken to the determination of product shelf life.

Microbial shelf life assurance testing provides the fundamental information to confirm and conclude a microbial risk assessment. It is the most effective way to validate controls designed to maintain product integrity. And, if time is an issue we have analytical models that can avoid impractical lengthy assessments.

We can offer 4 types of microbial shelf life assurance testing:

- Shelf life validation & verification testing

- Challenge testing

- Abuse testing

- Accelerated shelf life testing

Microbial shelf life assurance testing by premier analytical services can help you to determine, challenge and extend the shelf life of both new and existing products.

Useful Tools to Assess the Microbiological Safety and Quality of Foods

Shelf Life Validation and Verification

Microbial evaluation of a products ability to achieve its desired shelf life under the specified storage conditions. Either to validate that the target shelf life is achievable or to verify that it can be achieved by the working practises in place.

How is it performed?

The product is manufactured under typical conditions. Microbial test suites, customised for each product based on a predictive microbial risk assessment, are performed at regular intervals throughout the product’s entire target shelf life.

When do you do it?

Normally performed at NPD trial stage. It is best used when the microflora is inherent in the product or where the environmental flora is well understood and unlikely to vary.

Pros

Builds confidence in the products ability to achieve its intended microbial stability under specified storage conditions by examining the effect of natural microflora.

Cons

Relies on the presence of natural flora at a single production time point so it is specific for the conditions of manufacture at the time the test batch was made. It does not challenge the potential variation in microflora that may be present. As such it does not provide a robust challenge of a products microbial stability as determined by its intrinsic and extrinsic factors.

Challenge Testing

What is it?

A positive challenge of the microbial stability of both product and production process.

How is it performed? The product is inoculated with a cocktail of stress-conditioned microorganisms selected by predictive microbial risk assessment. Sub lethal stress conditioning develops the inherent strength and stability of the organisms such that they survive introduction to the new environment and provide the most robust challenge. The microbial tests performed at regular intervals are customised to detect those microorganisms present in the inoculum.

When do you do it?

At NPD stage to establish shelf life for new products or to extend shelf life of existing products. Especially useful if time constraints prohibit evaluation across entire target shelf life.

Pros

Provides robust information to complete a microbial risk assessment. Not often required to last for the full duration of target shelf life. The likely period over which growth and death would be seen can be estimated as part of the predictive microbial risk assessment and meaningful evaluations obtained which when extrapolated negate any requirement for impractical lengthy assessments.

Cons

Negative controls are required. These can however double up as shelf life validating tests.

Abuse Testing

Evaluation of the microbial stability of both product and production process under adverse conditions.

How is it performed?

Typically either intrinsic, extrinsic or both parameters are altered. The altered ‘abuse’ state will be well controlled and compared to standard state.

When do you do it?

When customer abuse may be an issue or to investigate product and process issues.

Pros

Provides insight into product performance under worse case scenarios.

Cons

May not be indicative of shelf life attainable under normal conditions.

Microbiology

| Microbial Shelf Life Assurance Testing | ||

| Each food product is different such that they will require different analytical protocols to establish their Microbial Shelf Life.

We therefore adopt a 3 phased approach as follows in order to customise an experiment designed to establish the Microbial Shelf Life of a particular product. Phase 1: Data collection Phase 2: Microbial risk assessment and Shelf Life Test design. Phase 3: Shelf Life Test Phase 1: We ask you to complete our ” Microbial Shelf Life Assurance Testing Data Collection Form”. We utilise the product and process information you provide in this form along with measurement of the product’s Water Activity (Aw) and pH to carry out a microbial risk assessment. It is recommended that Aw and pH are measured in triplicate i.e. on 3 different samples (ideally at start of life across at least two batches). Phase 2: A microbial risk assessment is carried out based on the data obtained in Phase 1 . We then report this to you along with our recommendations regarding the best analytical model to test the shelf life of your product. We also provide a quotation with regard to how much it would cost for us to go on and carry out this recommended shelf life test. Phase 3 The shelf life test is then carried out in line with recommendations and costs as advised. |

||

| CIMSCEE (Comite des Industries des Mayonnaises et Sauces Condimentaires de la CEE – Committee of the Industries of Mayonnaises and Table Sauces of the European Economic Community) | ||

| Protocol for both predictive and analytical assessments of the microbial stability and safety of acetic acid based foods | ||

| CIMSCEE | By calculation from chemical analyses | Chemical analyses include:

Acetic acid by HPLC Sugar profile Moisture pH Salt by Sodium |

| CIMSCEE | Evaluation of STABILITY by Challenge Test | |

| CIMSCEE | Evaluation of SAFETY by Challenge Test – if required | |

| Other Microbiology Consultancy Services | ||

| Charged appropriately in line with level of work required | ||

Accelerated Shelf Life Testing

What is it?

Physically altering an extrinsic parameter, such as storage temperature, in order to assist agents of product deterioration

How is it performed?

Most often storage temperature is maintained at a higher level with the aim of improving microbial growth kinetics

When do you do it?

When shelf life evaluation is required within a reduced timeframe compared to the target shelf life

Pros

Application restricted to scenarios wherein product intrinsics are thermo-stable and the hazard organisms are known to occur at low temperature but their growth kinetics are increased at elevated temperature such that an early warning can be given regarding product stability.

Cons

The alteration of an extrinsic parameter gives a false representation of the product profile such that intrinsics may change. The potentially problematic microbial population may not be suited to development in this altered environment such that resultant lack of growth could impart a false sense of security. Additionally cascade effects at lower temperature could be missed.

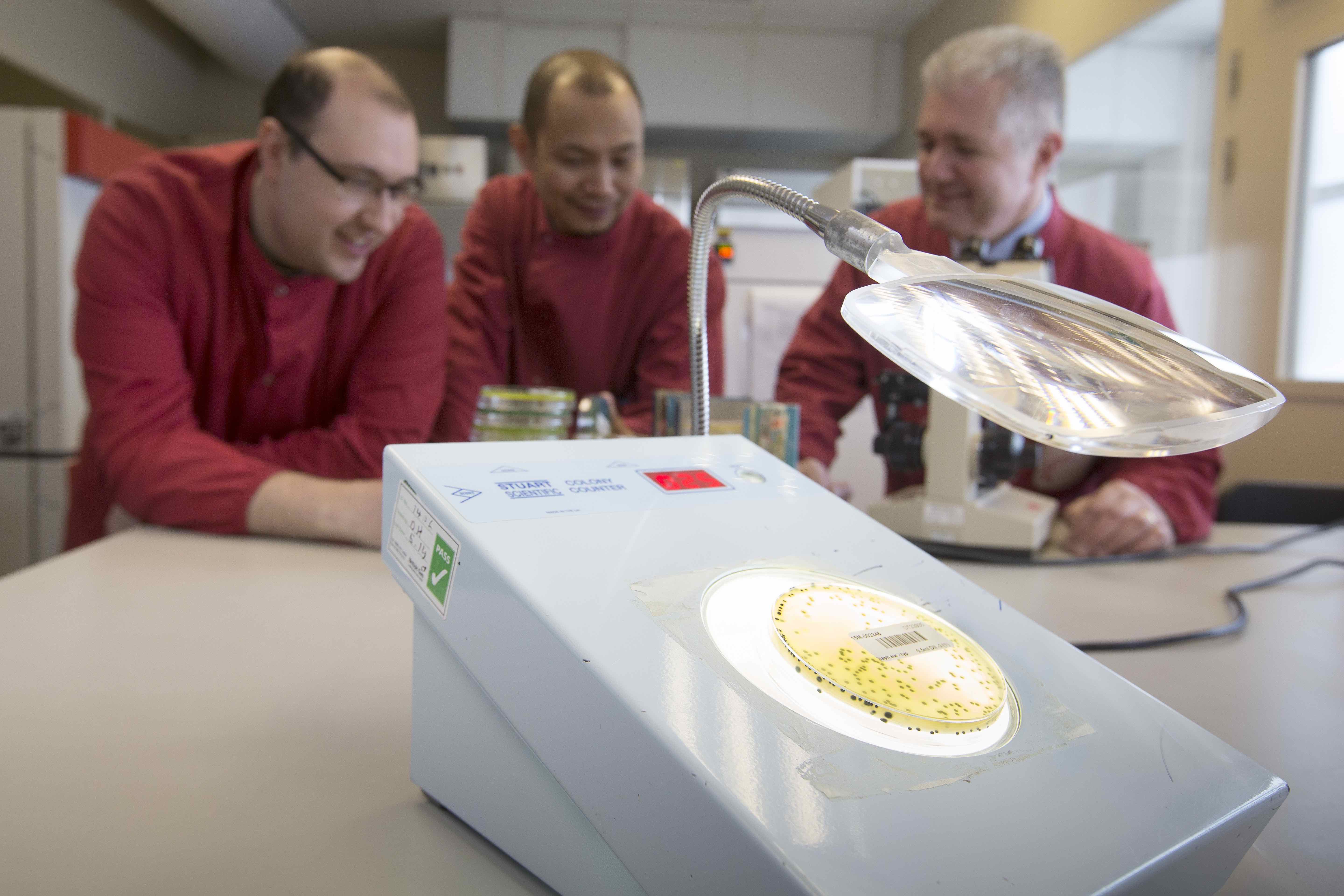

Microbiology

Maintenance of product safety and quality throughout shelf life is the aim of all food producers.

Deterioration due to microbial activity can be a major threat to both the quality and safety of most food products. It is therefore essential that a systematic approach is taken to the determination of product shelf life.

Microbial shelf life assurance testing provides the fundamental information to confirm and conclude a microbial risk assessment. It is the most effective way to validate controls designed to maintain product integrity. And, if time is an issue we have analytical models that can avoid impractical lengthy assessments.

We can offer 4 types of microbial shelf life assurance testing:

- Shelf life validation & verification testing

- Challenge testing

- Abuse testing

- Accelerated shelf life testing

Microbial shelf life assurance testing by premier analytical services can help you to determine, challenge and extend the shelf life of both new and existing products.

Useful tools to assess the microbiological safety and quality of foods

Shelf Life Validation and Verification

Microbial evaluation of a products ability to achieve its desired shelf life under the specified storage conditions. Either to validate that the target shelf life is achievable or to verify that it can be achieved by the working practises in place.

How is it performed?

The product is manufactured under typical conditions. Microbial test suites, customised for each product based on a predictive microbial risk assessment, are performed at regular intervals throughout the product’s entire target shelf life.

When do you do it?

Normally performed at NPD trial stage. It is best used when the microflora is inherent in the product or where the environmental flora is well understood and unlikely to vary.

Pros

Builds confidence in the products ability to achieve its intended microbial stability under specified storage conditions by examining the effect of natural microflora.

Cons

Relies on the presence of natural flora at a single production time point so it is specific for the conditions of manufacture at the time the test batch was made. It does not challenge the potential variation in microflora that may be present. As such it does not provide a robust challenge of a products microbial stability as determined by its intrinsic and extrinsic factors.

Challenge Testing

What is it?

A positive challenge of the microbial stability of both product and production process.

How is it performed? The product is inoculated with a cocktail of stress-conditioned microorganisms selected by predictive microbial risk assessment. Sub lethal stress conditioning develops the inherent strength and stability of the organisms such that they survive introduction to the new environment and provide the most robust challenge. The microbial tests performed at regular intervals are customised to detect those microorganisms present in the inoculum.

When do you do it?

At NPD stage to establish shelf life for new products or to extend shelf life of existing products. Especially useful if time constraints prohibit evaluation across entire target shelf life.

Pros

Provides robust information to complete a microbial risk assessment. Not often required to last for the full duration of target shelf life. The likely period over which growth and death would be seen can be estimated as part of the predictive microbial risk assessment and meaningful evaluations obtained which when extrapolated negate any requirement for impractical lengthy assessments.

Cons

Negative controls are required. These can however double up as shelf life validating tests.

Abuse Testing

Evaluation of the microbial stability of both product and production process under adverse conditions.

How is it performed?

Typically either intrinsic, extrinsic or both parameters are altered. The altered ‘abuse’ state will be well controlled and compared to standard state.

When do you do it?

When customer abuse may be an issue or to investigate product and process issues.

Pros

Provides insight into product performance under worse case scenarios.

Cons

May not be indicative of shelf life attainable under normal conditions.

Microbiology

| Microbial Shelf Life Assurance Testing | ||

| Each food product is different such that they will require different analytical protocols to establish their Microbial Shelf Life.

We therefore adopt a 3 phased approach as follows in order to customise an experiment designed to establish the Microbial Shelf Life of a particular product. Phase 1: Data collection Phase 2: Microbial risk assessment and Shelf Life Test design. Phase 3: Shelf Life Test Phase 1: We ask you to complete our ” Microbial Shelf Life Assurance Testing Data Collection Form”. We utilise the product and process information you provide in this form along with measurement of the product’s Water Activity (Aw) and pH to carry out a microbial risk assessment. It is recommended that Aw and pH are measured in triplicate i.e. on 3 different samples (ideally at start of life across at least two batches). Phase 2: A microbial risk assessment is carried out based on the data obtained in Phase 1 . We then report this to you along with our recommendations regarding the best analytical model to test the shelf life of your product. We also provide a quotation with regard to how much it would cost for us to go on and carry out this recommended shelf life test. Phase 3 The shelf life test is then carried out in line with recommendations and costs as advised. |

||

| CIMSCEE (Comite des Industries des Mayonnaises et Sauces Condimentaires de la CEE – Committee of the Industries of Mayonnaises and Table Sauces of the European Economic Community) | ||

| Protocol for both predictive and analytical assessments of the microbial stability and safety of acetic acid based foods | ||

| CIMSCEE | By calculation from chemical analyses | Chemical analyses include:

Acetic acid by HPLC Sugar profile Moisture pH Salt by Sodium |

| CIMSCEE | Evaluation of STABILITY by Challenge Test | |

| CIMSCEE | Evaluation of SAFETY by Challenge Test – if required | |

| Other Microbiology Consultancy Services | ||

| Charged appropriately in line with level of work required | ||

Accelerated Shelf Life Testing

What is it?

Physically altering an extrinsic parameter, such as storage temperature, in order to assist agents of product deterioration

How is it performed?

Most often storage temperature is maintained at a higher level with the aim of improving microbial growth kinetics

When do you do it?

When shelf life evaluation is required within a reduced timeframe compared to the target shelf life

Pros

Application restricted to scenarios wherein product intrinsics are thermo-stable and the hazard organisms are known to occur at low temperature but their growth kinetics are increased at elevated temperature such that an early warning can be given regarding product stability.

Cons

The alteration of an extrinsic parameter gives a false representation of the product profile such that intrinsics may change. The potentially problematic microbial population may not be suited to development in this altered environment such that resultant lack of growth could impart a false sense of security. Additionally cascade effects at lower temperature could be missed.